Certified Magnetic Particle Inspection (MPI) Services

Detect surface and subsurface flaws in materials with certified magnetic particle testing for industrial and OEM applications.

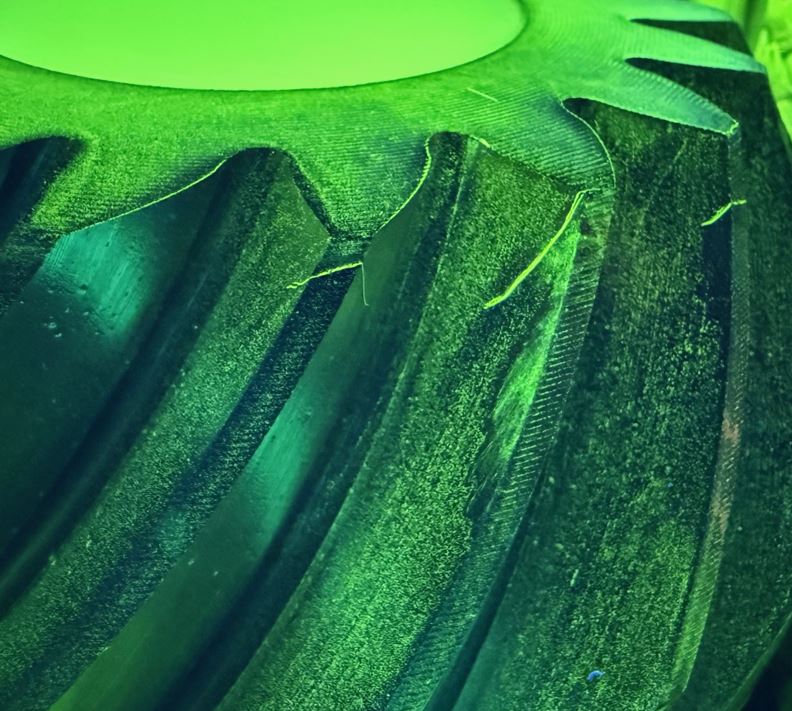

Magnetic Particle Inspection for Ferromagnetic Materials

Magnetic particle inspection (MPI) is a proven non-destructive testing (NDT) technique for detecting surface and near-surface cracks in ferromagnetic materials. We provide both wet bench inspections and portable yoke magnetic particle testing, ensuring flexibility for in-facility and field inspections. For additional depth assessment and flaw measurement, we may also recommend complementary testing such as our ultrasonic thickness testing services.

Certification Details

Our Magnetic Particle Inspection services are backed by certified professionals trained to meet the highest industry standards:

- ASNT ACCP Level 2

NDT Magnetic Particle Testing Capabilities

Our services are equipped to handle both high-volume inspection projects and field-based evaluations. We offer:

These setups allow us to perform efficient, repeatable inspections for surface and slightly subsurface defects in castings, welds, forgings, and other ferromagnetic parts. For detecting surface-breaking discontinuities in non-magnetic materials, see our Liquid Penetrant Inspection services.

Talk to an MPI Expert – Get Answers Now.

Our certified NDT magnetic particles specialists are ready to deliver fast, reliable inspection solutions tailored to your specific project needs.